When we say automation, PLC is one of the first products that come to mind. What is PLC? How many parts does PLC consist of? What does PLC do? Let's examine it briefly and concisely in our article.

SHORT ANSWER

English: "Programmable Logic Controller"

In its simplest form, we can define PLC as: "It is a special computer programmed to control certain processes in industries such as automotive, metal, furniture and textile."

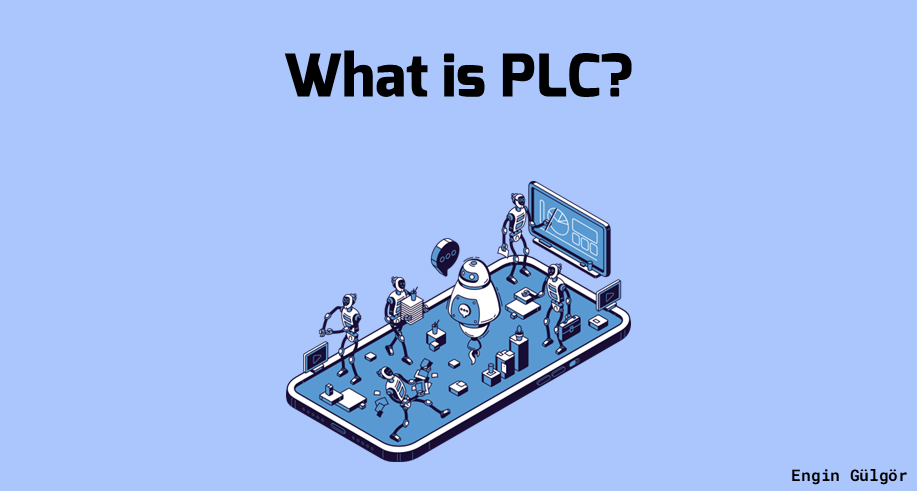

Each PLC simply consists of 3 parts. Input, CPU and Output.

- Input: Everything we receive from the machine and enter into the plc as information are our inputs. Limit sensors, level information, motor contactor or relay contacts, sensors, buttons, etc. We can show it as .

- CPU (processor): It is the part where all operations take place and gives intelligence to the PLC. The programs we write are processed in this section and the results are given to the outputs.

- Output: According to our PLC program, the results created by the CPU are given to the output units, such as valves, relays, motor drivers, lamps, etc. controls are provided.

One of the biggest advantages of PLC is that it has a structure that is more resistant to harsh physical conditions (dust, heat, impact, magnetic interference, vibration, etc.). That's why in many industrial automation fields, other processor cards (Arduino etc.) are not used, but PLCs are used.